-

About UsProductsCustomized SolutionProjectGalleryNews

The Importance of Uniformity in Woven mesh fabric for Consistent Performance

Release time: September 14, 2023The uniformity of Woven mesh fabric is directly related to its strength and durability. The uniform fabric structure ensures a balanced and stable interconnection between the fibers or lines in each part. If the fabric has uneven areas or tightness, it can lead to weak points and vulnerable areas. In contrast, a uniform fabric provides more consistent strength and durability, allowing it to maintain stable performance under stress and usage conditions.

Woven mesh fabric is commonly used in filtration and screening applications, such as solid-liquid separation, particle screening, etc. In these applications, fabric uniformity is critical. The uniform fabric structure ensures that the material is evenly distributed in the mesh to avoid clogging or leakage problems. Only the uniform mesh size and distribution of the fabric can ensure consistent filtration and screening results and provide reliable performance.

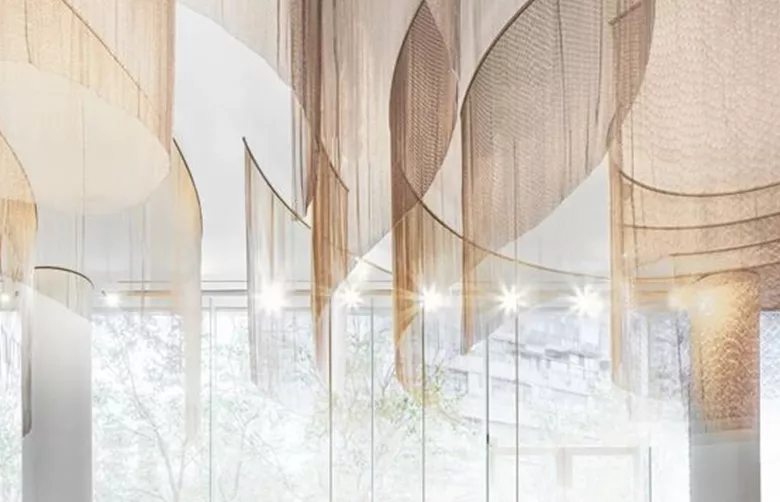

For applications that require light transmission, such as building shading, indoor lighting, etc., the uniformity of Woven mesh fabric plays an important role in the penetration and distribution of light. A uniform fabric structure ensures that light is evenly dispersed across the fabric, avoiding noticeable shadows or uneven lighting. This uniformity can provide consistent light transmission, achieving the desired shading or lighting effect, while maintaining visual comfort and continuity between indoors and outdoors.

The uniformity of Woven mesh fabric also directly affects its surface texture and appearance. Uneven fabric structure may cause surface wrinkles, distortion or unevenness, affecting the overall appearance and texture. In contrast, uniform fabrics provide a smooth, flat and consistent appearance, adding to the visual appeal and quality of the product.

Recommended News